Carving for Industrial Purposes

- Rupert Eachells

- Mar 18, 2021

- 2 min read

Carving for industrial purposes is very different to carving for a hobby, for fun or creating a bespoke piece of furniture!

Businesses that produce period style furniture, have to look for cheaper and easier ways to carve, in order to make a profit. One way they do that, is by using softer, easy to shape timbers. Unless the client insists on the using their choice of timber, which I personally think is proper, and honest, they will use a soft timber, which is much easier to carve. One good example of this are pipe shades, which are used on pipe organs. If the shades are gilded in gold leaf, then that’s OK (you won't see the colour or grain of the timber in the finished piece), but if they have a natural finish, in my opinion, the same timber as the rest of the organ should be used.

Carving on American White Oak, is not one of the easiest timbers to carve!

Softer timbers are often used for gilded or painted mirror frames, and are fine. I recall designing and carving a mirror frame in the 1980’s, in which I used Western Australian Jarrah wood, mainly for the exercise and experience. It is one of the hardest timbers I’ve ever used, but good to carve, once you understand how to "control" the grain. It is also more predictable than many imported timbers. For example, it is much better than White Oak. English Oak is my favourite of the oaks, but unfortunately has become very scarce over the last 30 years.

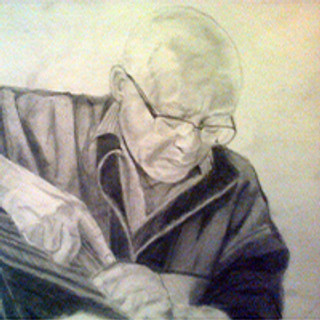

Left - The mirror frame I carved in West Australian Jarrah, was one of the hardest I have carved, and became a favourite.

When carving for industrial purposes, you are expected to carve in given time, irrespective of the type of timber! Over the years, wood carvers have found ways to make carving quicker for doing multiple pieces, where they can use the same tools on 10 legs at a time. If you are doing chair legs, where you may have 32 legs with the same design for eight chairs, then it makes sense, as this kind of work is repetitious and can be very monotonous.

Carving multiple chair legs at the same time. The process can be seen in the video below.

Comments